All Wood Types / Engineered

Engineered Hardwood Flooring

At Vermont Plank Flooring, we take the recipe for engineered wood flooring and dramatically improve upon it. We fuse the highest quality materials and then stir in the most advanced technologies to create wide plank engineered flooring that is far superior to the industry standard.

By slicing hardwood into thin plies, and then restacking them with the grain running in alternate directions, you create an incredibly strong and stable structure. Top that with a layer of your chosen locally sourced hardwood (or premium pine) species, and you have flooring that is as beautiful as it is sturdy.

CARB 2 Compliant

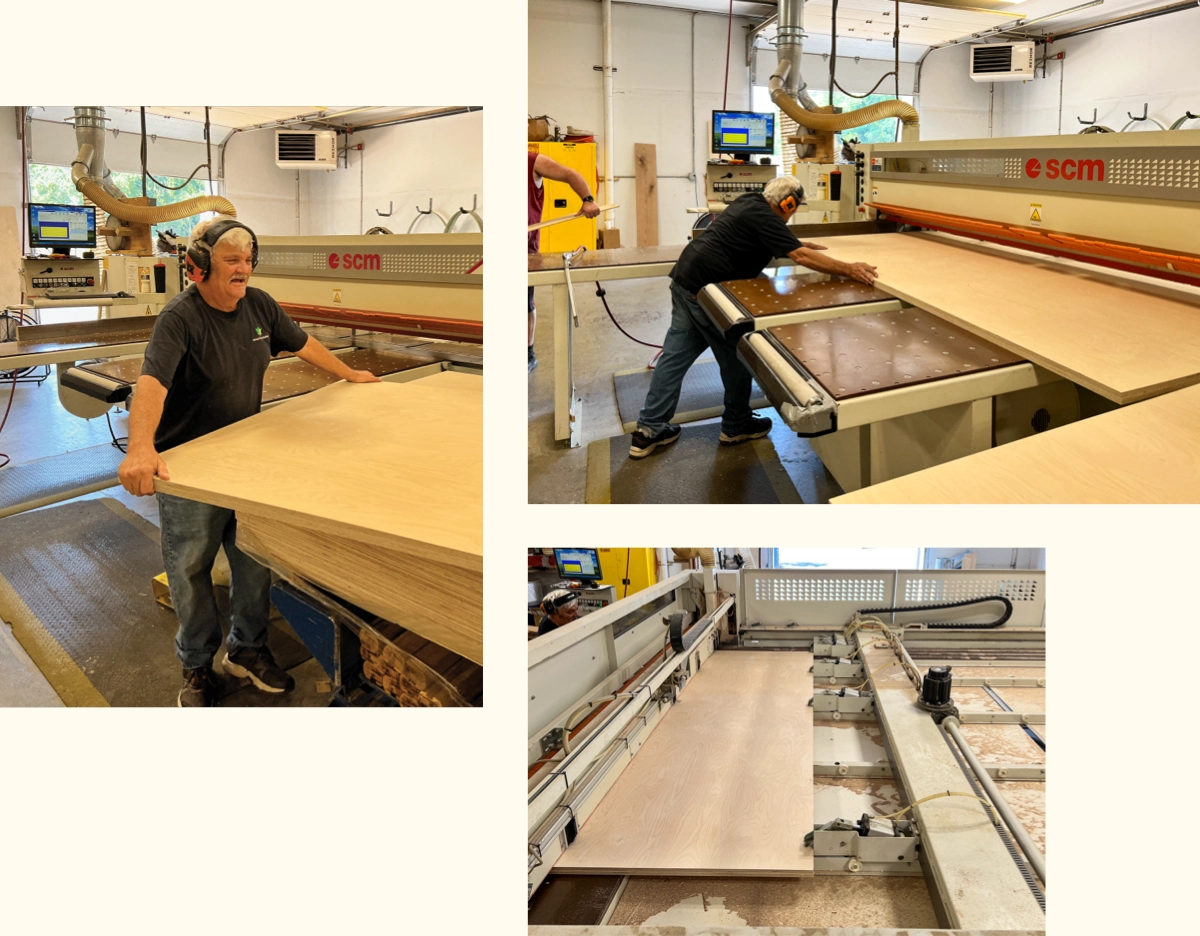

Constructed 100% In-House at our Solar-Powered Vermont Mill

Our Engineered Hardwood Flooring exceeds CARB 2 standards. Crafted in our 100% Solar Powered, Zero-Added-VOC facility, Vermont Plank's engineered flooring meets the highest standards of indoor air quality.

The Vermont Plank Difference: Our Engineered Flooring Process

Our engineered wood planks are made of a 6.4mm thick layer (called a lamella) of hardwood, laminated to a substrate of cabinet-grade birch plywood.

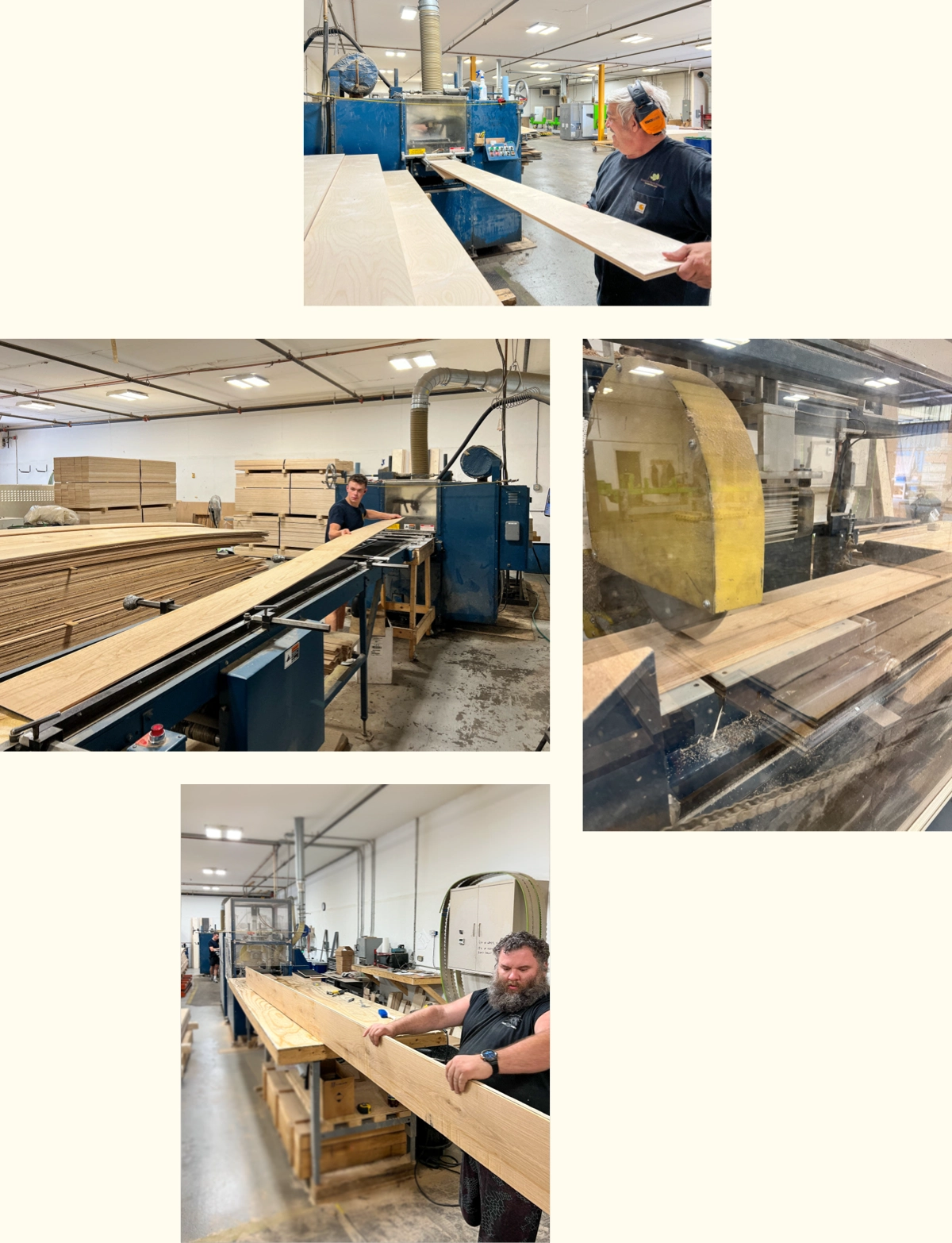

In our lamella room, the 22-millimeter thick planks are passed through a band saw, which peels a 6.4-millimeter thick slice from the top side of the board with each pass.

Two passes result in three identically thick lamellas, with 1.4 millimeters lost to the thickness of the blade itself on each pass. The lamellas are then fed through a brush machine to clean the surfaces.

Meanwhile, the adjacent beam saw rips a 4-foot by 8-foot sheet of the highest quality 15-millimeter-thick cabinet-grade plywood into planks that match the width of the lamellas, up to 12 inches maximum. The beam saw does this with incredible efficiency, making up to four cuts simultaneously on each plywood sheet.

The freshly cut plywood planks and lamellas are then brought to the glue applicator where hot melt glue, heated to 295°F, is measured precisely and rolled evenly on the plywood. The lamellas are then glued down to the plywood and passed through a five-roller press exerting 1,000 pounds of force per square inch to assure an incorruptible bond. To confirm the quality of that bond, samples are cut and alternately soaked in water and heated in ovens for various lengths of time, with multiple checks for adhesion failure throughout the process.

After passing this quality check, the planks are cut to length along the seam of the lamella by a flying saw, and finally, sent back to the molder room. There, the glued-up engineered planks are milled into 3/4"-thick flooring, with a tongue and groove edge profile and end-matching.

Learn more about our milling process on our Production Page here >>

Vermont Plank Engineered Hardwood Flooring Reviews

Kristine Virsis

Kristine Virsis

Recently had Vermont Plank floors installed and are in LOVE. Their customer service was great every step of the way, we're new to home renovation so it was so nice to have that constant support. I could call Gary anytime and he'd help 🙂 The product is gorgeous. I chose character grade because I like the rustic look and have been getting so many compliments. Also chose the engineered and the layer of Oak is SO thick, basically indistinguishable from hardwood. We're so super happy. Fully recommend.

![]() Posted on Google

Posted on Google

Alexander E

Alexander E

Fantastic products, great people I am completing my second project with them. About 7 years ago I moved to Vermont and bought hickory hard floors from them for my house. Now, 7 years later, those floors still look wonderful, like new, despite my dogs running on them back and forth. Moving again now, and this time I ordered engineered and finished ash floor from them. Another gorgeous floor and absolutely great technical support on any question relating to the installation. I almost wish to move again, to get yet another floor from them!

![]() Posted on Google

Posted on Google

Jade Sprague

Jade Sprague

I am very pleased with my purchase from VTPF. I ordered white oak floors for my home renovation. My foundation is a concrete slab, so I was forced to leverage an engineered material. I was so worried about using an engineered wood from an aesthetics perspective (as opposed to traditional hardwood), that I spent triple the time researching the flooring materials — I am so glad I did. The quality of the wood is palpable and is among my favorite features in the house. I get nonstop compliments on the floors and could not be happier with how they turned out. The customer service was also stellar.

![]() Posted on Google

Posted on Google

Sue

Sue

Vermont Plank Flooring is the best. I chose an engineered hickory with a natural finish. The floor is beautiful. The service and expertise in selecting and advice in installing the floor was top notch. I would highly recommend this company for their great floors and great service. Couldn't be more pleased.

![]() Posted on Google

Posted on Google

K

K

Great product with a great process that includes quality checks and approvals all along the way. If you are looking for a real wood or engineered wood floor you'll be very happy with Vermont Plank.

![]() Posted on Houzz

Posted on Houzz

Susan H

Susan H

Excellent quality of flooring. The person installing the wood floors was impressed with the quality of the engineered wood and the way it was milled.

![]() Posted on Google

Posted on Google

To a traditionalist, engineered hardwood flooring may seem objectionable. The term “engineered” implies it was designed and constructed, as opposed to having simply grown in the woods, fueled by sunshine, soil, and rain.

And in many cases, that traditionalist makes a good argument. Unadulterated solid wood is beautiful and sturdy and pure. But it has limitations.

Solid wood, as a formerly living entity, continues to react to its environment, most noticeably by expanding and contracting due to changes in temperature and humidity, and by warping, buckling, or splitting if it is in prolonged contact with excessive wetness.

As such, in locations that regularly confront moisture, the stability of engineered planks is recommended to combat movement and degradation. And one doesn’t have to live in a rainforest to encounter excessive moisture.

Planks laid in bathrooms, laundry rooms, below grade in basement rooms, or anywhere when laid directly on concrete, all have the potential for degradation due to moisture, even in relatively dry climates.

Would you like an Engineered Hardwood Floor in your home?

Call +1.866.481.5307 to speak with one of our flooring specialists.

Or, simply request a sample or quote.